Introduction

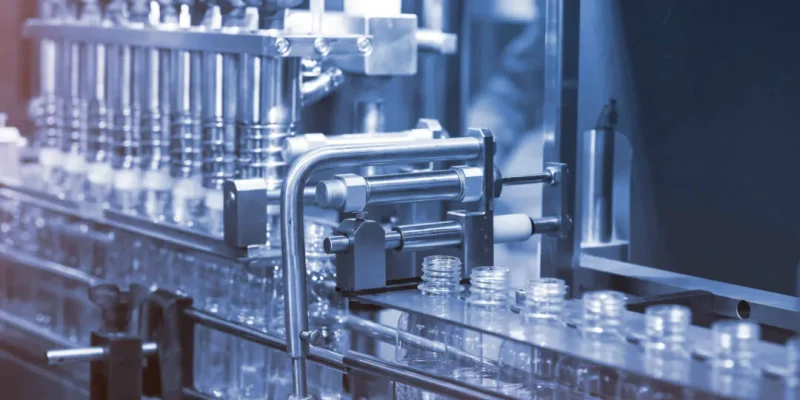

Capping machine manufacturers play a vital role in ensuring efficiency, consistency and safety across countless industries. From pharmaceuticals to food and beverage production, the need for precise and reliable packaging solutions has never been greater. A strong supply chain and dependable manufacturing partner can help companies maintain quality while meeting the demands of today’s fast-moving markets.

Why Capping Machines Matter

At the heart of every successful packaging line lies a capping system that works without fail. Caps may look small and simple, yet they carry huge responsibility. They seal in freshness, prevent contamination, and create trust between brand and consumer. Without the right machine in place, even the most carefully formulated product could lose its value.

The importance of capping machines is felt across sectors:

Food and drink

Ensuring freshness and leak prevention.

Pharmaceuticals

Protecting medicines with tamper-evident closures.

Cosmetics

Preserving product quality and presentation.

Chemicals

Safeguarding users and transport through reliable sealing.

When a closure fails, it is not just a production issue but a brand reputation risk. This is why businesses worldwide are increasingly attentive to their choice of equipment.

Types of Capping Machines Available

Manufacturers design machines to suit a wide range of applications. The choice depends on the type of container, the style of cap, and the speed of production required.

Common models include:

Screw cappers

Used widely for bottles with threaded caps.

Snap cappers

Designed for lids that press into place with speed.

Corking machines

Essential for industries like wine where tradition meets technology.

Speciality cappers

Built for complex closures or unique packaging.

Each type offers distinct advantages, and the best manufacturers provide flexibility to customise solutions. For businesses scaling up, versatility is often more valuable than sheer speed.

Qualities to Look for in a Manufacturer

Selecting the right partner is about more than equipment. It is about reliability, service and a shared commitment to excellence. Businesses in Singapore have often remarked on the value of manufacturers who focus on responsiveness and technical expertise.

Key factors to consider include:

Experience and expertise

Look for a proven history of delivering durable and precise machines.

Innovation

Modern manufacturers integrate automation, digital controls and data tracking.

Support and maintenance

After-sales service ensures uptime and reduces long-term costs.

Scalability

Equipment should adapt as production grows.

Compliance

Machines must meet international safety and hygiene standards.

A Singaporean manufacturer once observed, “In this industry, consistency is not negotiable. Every cap must perform as if it were the first one tested on the line.” This mindset highlights why the choice of supplier is as critical as the machine itself.

Trends Driving the Industry Forward

Like much of modern manufacturing, capping solutions are evolving rapidly. Today’s leading machines combine speed with intelligence.

Notable trends include:

Automation

Robotics and sensors reduce errors and boost productivity.

Sustainability

Energy-efficient systems support greener production goals.

Flexibility

Machines that handle multiple cap types reduce downtime.

Data-driven control

Real-time monitoring helps detect issues before they disrupt production.

These advancements mean businesses can expect not only better performance but also lower operational risks. They also align with consumer expectations, as more buyers demand sustainable packaging practices and transparency in production processes.

Benefits of Working with Reliable Manufacturers

Building a partnership with skilled capping machine producers delivers both immediate and long-term rewards.

Cost savings

Well-engineered machines cut waste and reduce downtime.

Quality assurance

Each product reaches customers sealed and protected.

Reputation

Strong packaging safeguards brand credibility.

Peace of mind

Ongoing support keeps lines running smoothly.

As one Singapore-based expert put it, “A good capping machine is invisible to the consumer. The product simply feels secure, and that is how trust is built.”

Questions to Ask Before Investing

Before committing, businesses should engage manufacturers with thoughtful questions.

- What industries do you specialise in?

- How do you handle after-sales support and training?

- Can your machines scale with our future needs?

- Do your solutions comply with local and international standards?

- What is the average lifespan of your machines with regular maintenance?

These discussions build clarity and prevent costly surprises. They also provide a chance to test whether the manufacturer values long-term partnership over short-term sales. For many companies, the answers to these questions determine whether the investment will strengthen production capacity or become a costly burden.

The Future of Capping Machine Technology

Looking ahead, the industry is set for further transformation. Digitalisation is likely to play a central role, with manufacturers experimenting with artificial intelligence to predict maintenance needs and optimise production flow. Machines may soon adjust themselves automatically to different container types, minimising downtime and labour costs. In addition, greater emphasis will be placed on sustainability, not just in energy use but in helping brands support recyclable and eco-friendly packaging.

For businesses, this means that selecting a manufacturer is not only about what the machine can do today, but also about how the supplier plans to innovate tomorrow. A forward-thinking manufacturer ensures that the equipment purchased today does not become outdated within a few short years.

Conclusion

Capping machine manufacturers are more than suppliers; they are partners in quality, safety and growth. The right choice can safeguard product integrity, streamline operations and strengthen consumer trust. As industries evolve, it is those manufacturers who continue to innovate, support sustainability, and invest in smarter technology that will provide the strongest foundations for success. For companies across industries, the path to reliable packaging starts by finding trusted and innovative capping machine manufacturers

Comments